Give us a call or provide your contact details below, and a Dentsply Sirona representative will be in touch soon.

Successful collaboration between Fraunhofer scientists and Dentsply Sirona: Award goes to ZLS researchers

The Fraunhofer-Gesellschaft (Fraunhofer), Munich, a globally recognized link between basic research and applied sciences, awarded its renowned Joseph von Fraunhofer research prizes on May 8, 2019. In the category "Technik für den Menschen" [Human-Centered Technology], Dr. Bernhard Durschang and Dr. Jörn Probst from the ISC (Fraunhofer Institute for Silicate Research, Würzburg, www.isc.fraunhofer.de) won the award with the prosthetic material ZLS (zirconia-reinforced lithium silicate). A wealth of ideas and successful collaboration with industrial partners, including Dentsply Sirona Lab (formerly: DeguDent), contributed to the success, but the main factor here was courage.

Charlotte/Bensheim. German Chancellor Dr. Angela Merkel did not miss out on personally appearing at the awards ceremony and making a welcome speech, which included offering her congratulations for the big anniversary (70 years of Fraunhofer). "The Fraunhofer Model is a shining example of successful collaboration between science and the economy," she said, outlining in her speech a whole series of various fields of innovation, from digitalization to artificial intelligence and robotics, right through to battery cell production.

In the category "Technik für den Menschen" [Human-Centered Technology], the Fraunhofer-Gesellschaft honored two researchers who developed a new material for prosthetic restorations in collaboration with the industry. The high level of effort with which the partner Dentsply Sirona carries out its research and development paid off. Dentsply Sirona's investments in this field amount to around 150 million dollars each year. This results in a multitude of innovations in the digital and analog fields of dentistry. The high number of equally competent and motivated employees in the various research departments secures the company's leading role and makes it the partner of choice for universities and other scientific institutes. "The project to develop ZLS shows an outstanding example of these successful collaborations," said Dr. Markus Vollmann, Research & Development at Dentsply Sirona Lab.

Why did it need such a high level of courage? Quite simply because the researchers attempted something that was supposedly physically impossible. Until six years ago, glass ceramics were considered to be exhausted for use in dentistry. People were more or less resigned to this fact: Zirconia ceramics for structures with high strength (e.g., posterior bridges) and glass ceramics for beautiful, high translucency, but with considerable limitations regarding the indication.

If you explore the topic further, until six years ago there were two types of glass ceramics available on the market: The conventional variant was able to be integrated directly after milling. The high-strength lithium disilicate, however, stood out due to its higher strength and its ability to (non-adhesively) bond with glass ionomer cement. However, this material required subsequent process steps such as crystallization firing (20-40 minutes).

A block for all cases

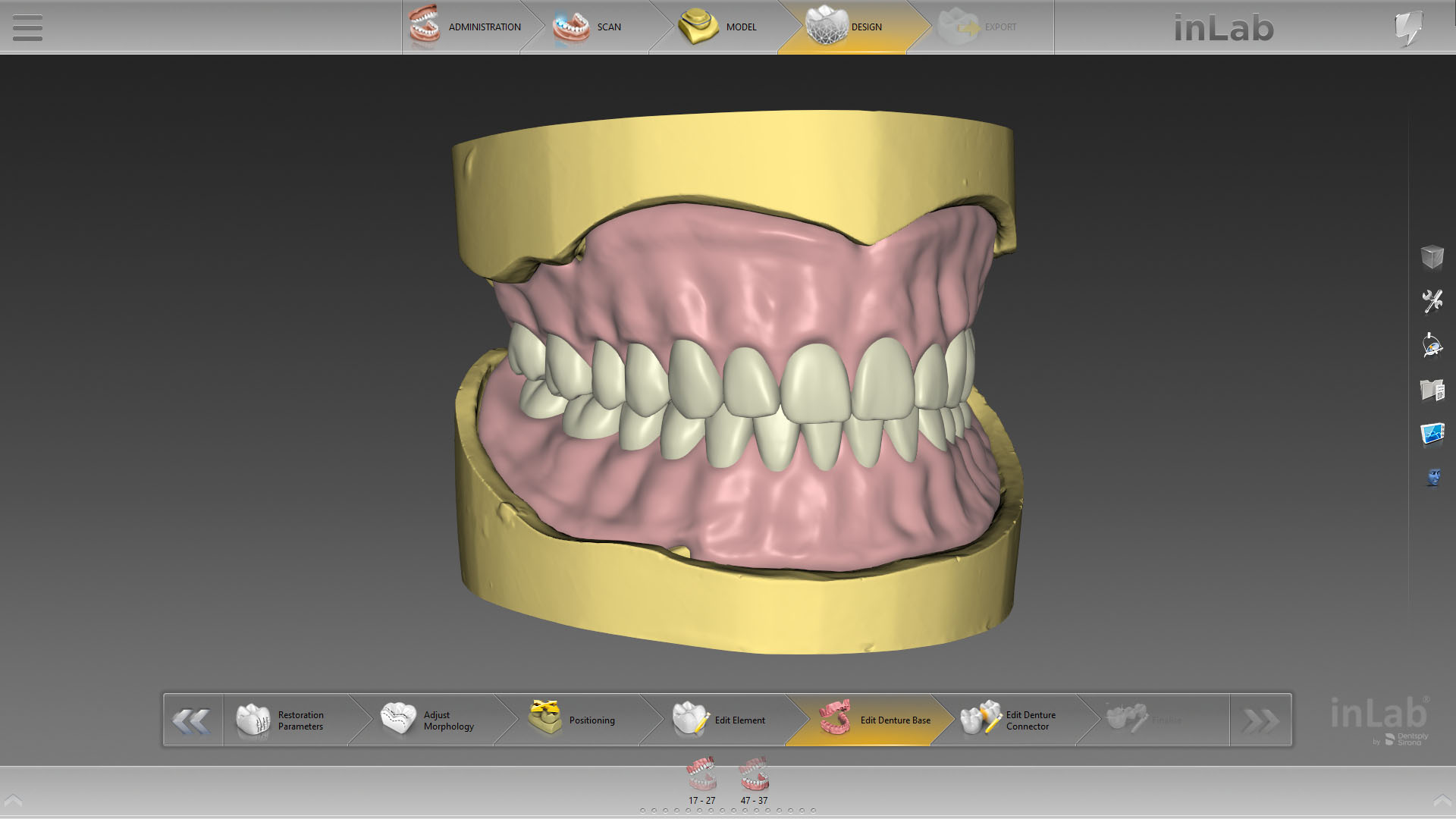

A handful of researchers did not want to accept that the status quo that existed at that time is the best option. Therefore, the joint efforts of the Fraunhofer researchers and the industrial companies involved (DeguDent, Vita Zahnfabrik) produced CAD/CAM blocks for all cases (e.g., Celtra Duo) in 2013. This resulted in a combination of the beneficial properties of zirconia and lithium disilicate. After grinding, the (single tooth) restoration could be inserted immediately (e.g., for inlays, onlays, partial crowns) or it could be glaze fired to give it the strength of lithium disilicate (e.g., crowns), now going clearly beyond this.

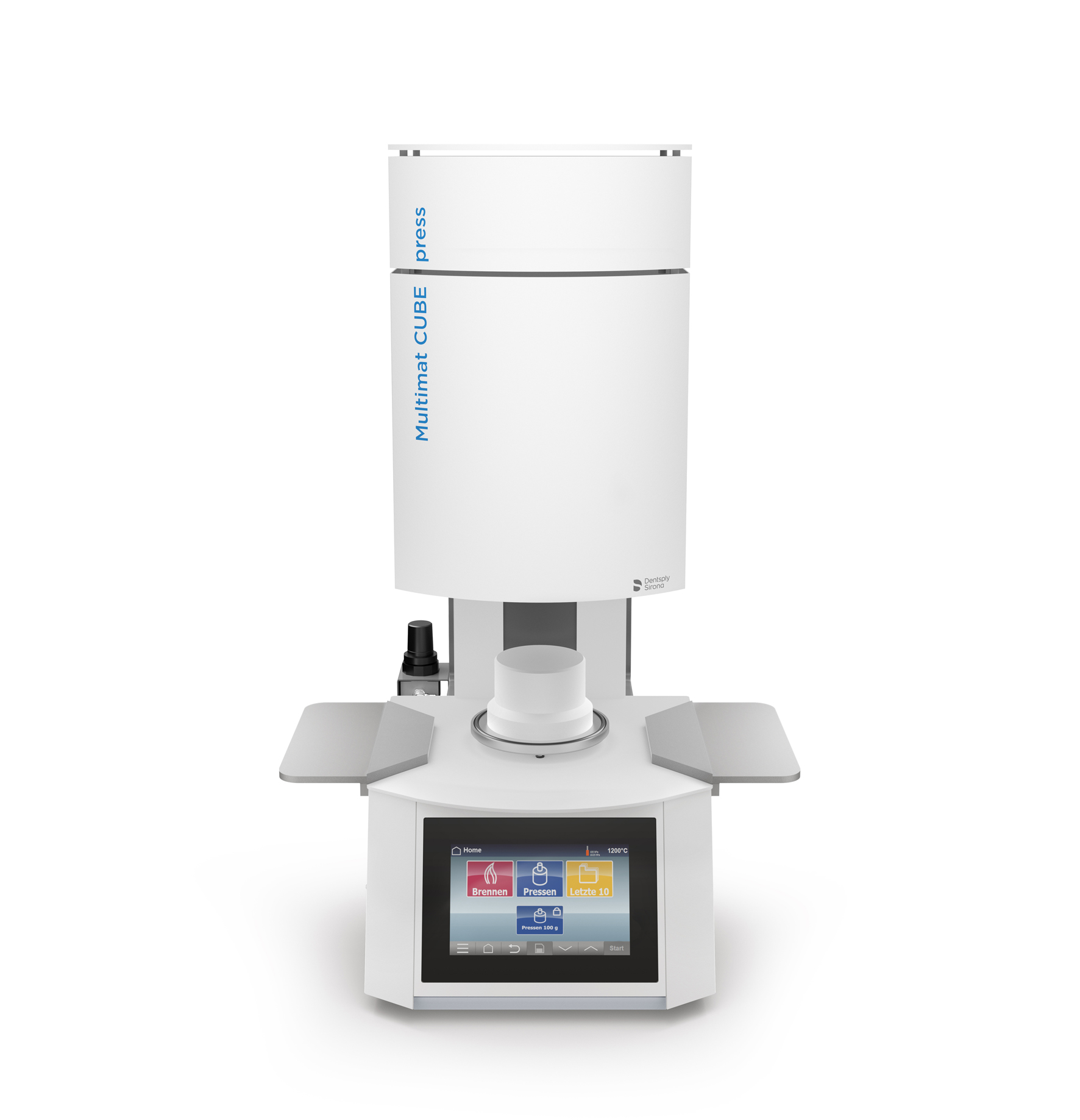

Furthermore, pressable ZLS (e.g., Celtra Press, Dentsply Sirona Lab) is now available. Dental technicians value it for both its esthetics and its higher strength. It even allows three-unit bridges in the anterior tooth region up to the second premolar as the terminal abutment.

An essential requirement: The course of development enabled the microstructure and surface quality of high-strength glass ceramics to be significantly improved. This allowed fields to be explored such as those that – putting it mildly – no-one had ever thought possible.

Complete analytical method specifically for ZLS research

At the industrial partner Dentsply Sirona Lab (or DeguDent), the material testing team developed a number of things including a new method specifically for the analysis of crystal distributions and densities. This does not require the usual etching of the test specimen. Differential thermal analysis (DTA) was also used. This helped to clarify how the structure behaves at different temperatures, where phase transitions occur, and how they affect the manufacturing process. Even the researcher group was amazed by how well its ZLS could ultimately be milled in the machine, e.g., the inLab MC XL (Dentsply Sirona Lab), in its final, crystallized (tooth-colored) state.

Since then, zirconia-reinforced lithium silicate has become a key all-ceramic material as it enables the dental technician to make first-class restorations quickly and safely, impressing both dentists and patients. The result can always be predicted well, just like the effort required for it.

Press Contact

Sirona Strasse 1

5071 Wals bei Salzburg

Austria